Smooth Surface Oriented

Strand Board

(SS-OSB)

commonly used in construction and other applications. OSB is made by compressing and gluing

together strands of wood in specific orientations. Here are some features of Smooth Oriented Strand

Board:

product. It is made by compressing and bonding wood strands together with adhesives under high pressure and heat.

moisture-resistant than traditional plywood. However, it is essential to use proper waterproofing and sealing techniques in applications where exposure to moisture is a concern.

SS-OSB Strength

- Both sides are calibrated

- Less warping and bending tendency

- 180 degrees flat surface

- Density 700-750 KG/CBM

- Screw removal @ 1000 lbs + (450 Kgs +)

- Excellent strength to weight ratio

- Tested in labs for best in class screw holding capacity

- Termite, fungus, fire resistant

Surface Capabilities

- Edge banding

- Lacquer, painting and PU

- Melamine coating, Veneer, Melamine decorative paper

- Glass, High gloss laminate, Acrylic

- Can use all kinds of joineries like Mini fix, Dowel, Right Angle/ Left

Angle Connectors, Hinges, Screw joint, etc.

Application

systems, serving as beams, joists, and headers. It

is often used in conjunction with other building

materials to create load-bearing components.

part of a soundproofing system due to its

density and ability to dampen sound.

as sheathing for walls, roofs,

and floors. It provides

structural support and

serves as a stable base for

exterior finishes such as

siding or roofing materials.

in the construction of walls

and roofs, particularly in

residential and commercial

buildings. It offers excellent

strength and stability,

contributing to the overall

structural integrity of the

building.

as a subfloor material. It

provides a solid and stable

base for finished flooring

materials such as hardwood,

laminate, or carpet.

used for packaging & crating due to its

strength and rigidity.

Wildfires Are Getting Worse, So Why Is the U.S. Still Building Homes With Wood?

- Cost-effectiveness: Wood is often more affordable than alternative building materials,

such as steel or concrete. This makes it an attractive option for developers and

homeowners looking to keep construction costs down. - Renewable resource: Wood is a renewable resource, and sustainable non- forestry

practices can ensure a steady supply. Responsible clean environment management can help

offset the environmental impact of using wood for construction. - Energy efficiency: Wood is a natural insulator, providing good thermal performance.

Wooden structures can be energy-efficient, helping reduce heating and cooling costs. - Aesthetic appeal: Many people appreciate the natural beauty and warmth of wood,

making it a popular choice for residential construction.

Applications of SS-OSB

- Construction: SS-OSB is used for construction of the entire houses including roofing and

flooring, hotels and motels. - Roof Decking: SS-OSB is often used as a base material for roofing systems, providing a

sturdy and reliable surface for shingles or other roofing materials. - Wall Sheathing: SS-OSB panels are commonly used as an exterior wall covering, providing

structural support and insulation for buildings. - Subflooring: SS-OSB is an excellent choice due to its strength, stability, and moisture

resistance. - Furniture Construction: SS-OSB can create sturdy and durable furniture, such as

wardrobes, shelves, cabinets, and tables.

How is SS-OSB Made?

The manufacturing process of SS-OSB involves several steps:

- Logs are debarked and cut into strands. These strands are oriented in

specific directions to maximize the panel’s strength and performance. - The oriented strands are mixed with a resin binder and wax to enhance

moisture resistance. The mixture is then spread onto a mat and

compressed under high pressure and heat. - The SS-OSB panels are cut into desired sizes and undergo quality checks

before use.

Strength and Durability of SS-OSB

- One of the key advantages of SS-OSB is its exceptional strength and durability.

- The oriented arrangement of strands gives SS-OSB superior load-bearing

capacity, making it suitable for various structural applications. - SS-OSB panels also have excellent dimensional stability, meaning they are less

likely to expand or contract due to changes in temperature and humidity. - Additionally, SS-OSB is highly impact-resistant and can withstand heavy loads

without significant deformation. - This Board can be used vertically or horizontally but the STRENGTH will

remain the same due to over cross laying of STRANDS.

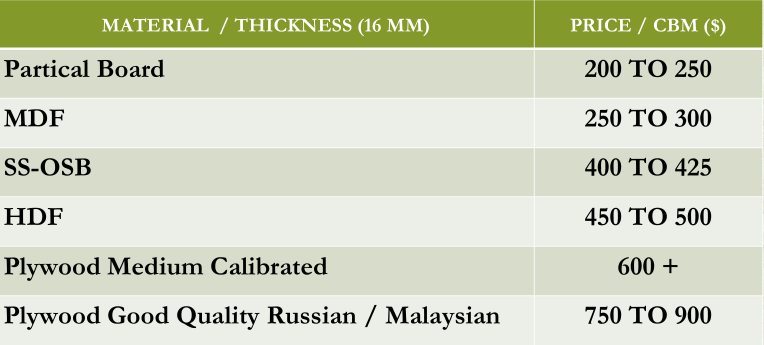

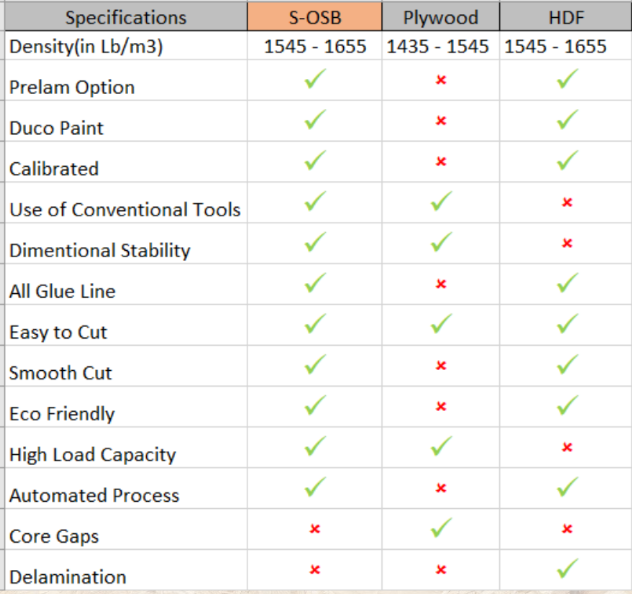

Comparision

Is SS-OSB stronger than plywood?

SS-OSB is generally stronger than plywood due to its oriented strand

arrangement and high density which enhances its load-bearing capacity.

Can SS-OSB be used outdoors?

SS-OSB can be used outdoors, but it should be protected from prolonged

exposure to moisture. Coatings or sealants can enhance its moisture resistance.

Is SS-OSB more affordable than plywood?

The price of SS-OSB is generally similar to plywood, but the quality that of

SS-OSB is far better than the Plywood making it a popular choice for

construction projects.

The Composition of SS-OSB

SS-OSB primarily comprises three layers: the surface layers and the

core layer.

- The surface layers are made of finer strands and are more tightly

compressed, providing a smooth and even finish. - The core layer consists of coarser strands and contributes to the

overall strength of the panel. - The strands are arranged in a crisscross pattern, creating a

structurally stable panel resistant to warping.

Advantages of Using SS-OSB

- Cost-Effective: SS-OSB is generally more affordable than plywood, making it

a cost-effective choice for builders and homeowners. - Versatility: SS-OSB can be used in many applications, including roofing,

flooring, wall sheathing, and furniture construction. - High Strength: The oriented strand arrangement gives SS-OSB superior

strength, making it suitable for demanding structural applications. - Moisture Resistance: With the right treatment and coatings, SS-OSB can

resist moisture, making it suitable for humid environments. - Sustainability: SS-OSB is made from fast-growing wood species and is often

produced using sustainable forestry practices.

Price Comparision